Don’t wait another second — contact the Starmor team today to start planning your project!

Solar control window films improve the performance of existing glass by reducing the amount of heat, glare, and ultraviolet energy that comes through the glass. They work by changing how the glass reflects, absorbs, and transmits sunlight to make it more energy efficient. The result is cooler, more comfortable interiors and far more energy efficient windows.

Solar control films regulate the three components of solar energy: visible light, infrared (IR) heat, and ultraviolet (UV) radiation. By increasing solar reflection and selective solar absorption, the film prevents a large portion of infrared heat from passing through the window.

This reduces:

Dyed films work by absorbing part of the sun’s energy before it enters the room. They help with glare and moderate heat reduction but offer lower performance compared to metalized or nanotechnology films.

Metalized films use precision-coated metal layers to reflect a significant amount of solar heat. These films offer strong energy savings and are ideal for high-load environments but typically create a more reflective appearance on the glass.

All 3M™ Sun Control Window Films are made to be transparent and optically clear. The ultraviolet protection in the adhesive system is there to protect the adhesive, the metals, the polyester film, and the abrasion resistant coating from UV degradation. This UV protection will also help protect what is behind the film (home and office furnishings, artwork and floors), too. All Sun Control Window Films come with a scratch resistant coating for long term durability.

This is where 3M breaks the mold.

Prestige films use no dyes and no metals. Instead, they are constructed from over 200 layers of optically engineered nano-thin materials, each layer designed to manipulate light at the molecular level.

Here’s what makes this technology different:

Selective Heat Blocking

The layers are stacked to target and reject the most heat-producing wavelengths of IR energy without relying on metal. Prestige films can reject more heat than darker or more reflective films — even while remaining extremely clear.

Low Interior and Exterior Reflectivity

Because there are no metals, Prestige films avoid the mirror-like appearance common with reflective films. They maintain natural views and preserve building aesthetics.

Superior Performance in Hot Sunlight

Unlike metalized films that lose effectiveness as the sun’s angle changes, Prestige films become more efficient as sunlight becomes more intense, delivering consistent performance during peak heat hours.

Signal Friendly

No metals means no interference with cell signals, Wi-Fi, radio frequencies, or first-responder systems.

Prestige films represent the highest level of solar control without altering the look of the glass — a premium option for homes, schools, and buildings that want maximum performance with minimal visual impact.

Across Starmor’s window film lineup, including 3M™ Prestige, all films incorporate UV-absorbing technology that protects:

Furniture, flooring, and artwork

Retail merchandise

Window film layers and adhesives themselves

This dramatically slows fading and extends the life of interior assets.

3M™ solar control films are engineered to remain clear, stable, and durable. A scratch-resistant surface layer helps the film withstand cleaning and daily wear, ensuring long-term performance.

Solar control window films — especially advanced technologies like 3M™ Prestige — offer one of the highest returns on investment for comfort, efficiency, and protection. They form the foundation of Starmor’s broader protective solutions, supporting upgrades such as Riot Glass®, security screens, and decorative or privacy films.

Home window tinting provides multiple benefits, including:

Many homeowners choose window films as a cost-effective way to improve comfort, energy efficiency and security without replacing their existing windows.

Security window films can strengthen residential windows, making them more resistant to break-ins and impact. These films hold shattered glass together, preventing easy access for intruders while reducing the risk of injuries from broken glass.

Yes. Certain window films — especially reflective and tinted solar control films — can provide effective daytime privacy by making it harder to see into your home while still allowing natural light inside. For areas needing 24/7 privacy, frosted and decorative films offer full obscurity without blocking light. Starmor helps homeowners choose the right film for bedrooms, bathrooms, entry doors, and street-facing windows.

Sun control window film is one of the most cost-effective upgrades for commercial buildings. It reduces heat and glare, improves tenant comfort, lowers HVAC and utility costs, helps qualify for energy rebates, and creates a cleaner, more uniform building appearance.

Window film also supports safety, extends equipment life, and offers a sustainable alternative to adding more A/C capacity — making it a smart investment for property managers and building owners.

Window film installation is a precise, professional process performed by Starmor’s trained and certified 3M™ dealer technicians. Nearly all films are installed on the interior surface of the glass to ensure maximum performance and long-term durability.

1. Preparation of the workspace

We begin by protecting the surrounding area by placing drop cloths, covering flooring, and moving or shielding furniture as needed to create a clean, safe workspace.

2. Thorough glass cleaning

The glass is cleaned to remove dirt, paint, adhesives, and any contaminants that could interfere with adhesion. Clean glass is essential for a flawless installation.

3. Film wetting and positioning

The film is coated with a specialized slip solution (a mix of water and a mild detergent) that allows it to glide into place on the glass. This ensures precise alignment and a smooth, wrinkle-free fit.

4. Squeegee application

Using commercial-grade squeegees and proper installation techniques, our technicians remove the slip solution from beneath the film, bonding it cleanly to the glass surface.

5. Edge trimming and finishing

Once the film is set into position, the edges are carefully trimmed for a custom fit. A final squeegee pass seals the edges and removes any remaining moisture.

A small amount of water may remain under the film and will dissipate as it cures. Depending on film type and weather conditions, full drying typically occurs over several days to a few weeks.

All Starmor installations are IAW the IWFA Visual Standards to ensure clean lines, optimal film performance, and long-lasting results for every residential and commercial project.

Yes — professionally installed solar control window films can significantly reduce a building’s energy costs. By blocking a substantial portion of heat before it enters the building, window film reduces the load on HVAC systems, stabilizes interior temperatures, and lowers both cooling and demand-based utility charges.

Many commercial properties experience measurable energy savings within the first year, and most achieve a strong return on investment over the film’s lifespan. For businesses focused on reducing operating expenses, meeting sustainability goals, or avoiding costly HVAC upgrades, window film is one of the most effective improvements available.

The payback period for sun control window films depends on several factors — including glass type, film selection, sun exposure, local utility rates, and overall building performance. However, most projects see a 2–5 year simple payback, and some high-exposure commercial installations achieve returns in under 6 months.

Sun control films reduce heat gain, lower HVAC runtime, cut peak demand charges, and help stabilize interior temperatures — all of which contribute to long-term operational savings. For both businesses and homeowners, window film is one of the most cost-effective energy upgrades available, delivering measurable ROI along with improved comfort and reduced equipment strain.

Security window film strengthens existing glass by holding it together when struck, preventing it from shattering into loose pieces. Instead of breaking out of the frame, the glass stays bonded to the film, creating a flexible, tear-resistant barrier that delays forced entry and makes it far more difficult for an intruder to gain access.

By slowing down the attack and increasing the effort required to break through, security film gives occupants and staff more time to react and improves the chances of deterring the intruder altogether. While not a replacement for ballistic or forced-entry glazing, security film is an effective and affordable upgrade — and serves as a strong first layer in Starmor’s broader protection strategy.

Yes. While security window films are nor “Hurricane Proof”, they can help improve glass safety during hurricanes, tornadoes, and high-wind events by holding shattered glass together. While they do not stop debris impact or replace hurricane-rated systems, these films reduce the risk of flying shards — one of the most common causes of injury and interior damage during extreme weather.

When bonded to the frame with a proper attachment system, security film helps keep the glass intact even after breakage, buying valuable time and helping limit the spread of wind-driven debris inside the building. For homes and businesses in severe weather regions, window film is an effective and affordable upgrade that enhances overall protection.

Yes. Blast-resistant window films are engineered to hold glass together during an explosion or high-impact pressure event, reducing the risk of flying glass — one of the leading causes of injury in blast scenarios. When paired with a proper attachment system, the film helps keep the glass anchored to the frame, preventing dangerous shards from projecting inward.

While blast-resistant film does not stop the force of an explosion, it significantly improves occupant safety by minimizing glass-related injuries and limiting interior damage. These films are commonly used in government facilities, schools, commercial buildings, and other locations where enhanced protective measures are required.

Security window films can be applied to most common glass types, including standard annealed glass, tempered glass, and many insulated glass units (IGUs). However, the performance and safety benefits vary depending on the glass construction, thickness, and framing system.

Because every window behaves differently under impact, it’s important to work with a professional installer who can evaluate your glazing, recommend the correct film thickness, and determine whether an attachment system is necessary to meet your security goals. Starmor provides tailored assessments to ensure the film is matched to your specific windows, risks, and budget.

Security window films are ideal for a wide range of commercial properties, including:

Window film begins bonding to the glass immediately, but full drying and curing take more time. As the film cures, moisture trapped during installation slowly evaporates through the film’s surface. During this period, it’s normal to see small water bubbles, streaks, or a hazy, milky appearance — all of which disappear as the film dries.

Dry time depends on film thickness, weather conditions, sun exposure, and the type of glass. According to industry guidelines from the International Window Film Association (IWFA), typical cure times are:

Up to 4 mil (≤100 microns): 30–60 days

Most sun control and decorative films fall into this category.

4–8 mil (100–200 microns): 60–90 days

Many safety and light security films.

8–12 mil (200–300 microns): 90–110 days

Standard security films used for schools and commercial buildings.

Over 12 mil up to 17 mil (300–425 microns): 120–200 days

Heavier-duty security films designed for higher-impact protection.

Thicker films take longer to dry because they hold more moisture and require additional evaporation time.

The film will continue to clarify over several weeks or months.

Cold weather or shaded windows extend cure time.

Warm, sunny conditions speed it up.

Once cured, 3M™ Window Films will be optically clear and perform exactly as intended.

Most films look good quickly, but full curing can take anywhere from 30 days to six months, depending on the film type. This is completely normal — and part of the engineered performance of high-quality window films.

Absolutely. DIY window films are available at hardware stores and online, but professional-grade window films should only be installed by certified, trained, and authorized installers. High-performance films, especially solar control, safety, and security products, require precise preparation, alignment, and squeegee techniques to ensure proper bonding, optical clarity, and long-term durability.

Starmor’s installers are professionally trained and certified to apply 3M™ window films correctly, ensuring you receive:

A clean, distortion-free installation

Maximum film performance

Proper curing and adhesion

Full manufacturer warranty protection

While DIY films can be a quick solution, they cannot match the appearance, longevity, or performance of a professionally installed system. Besides, it’s a lot more work than people think.

Don’t do anything for the first 30 days after installation. The film needs to dry out and the adhesive needs to cure. After your window film has fully cured — typically 30 days after installation — you can clean it just like normal glass. Standard household cleaning solutions, including ammonia-based products like Windex®, are safe to use. For best results, use a soft, lint-free cloth, microfiber towel, or a clean squeegee.

To protect the film’s scratch-resistant coating, never use abrasive pads, scrub brushes, or harsh cleaning materials, as they can damage the surface.

With proper care, your Window Films will stay clear, clean, and high performing for years.

High-quality window films installed by Starmor are engineered to last for many years. The exact lifespan depends on the type of film, the glass it’s applied to, whether it’s an interior or exterior applied film and the local climate. Most modern films deliver long-term performance well beyond their warranty period.

In typical conditions:

Most films last 15+ years

Many installations continue performing 20 years or longer

Commercial warranties generally cover 10–15 years

Residential warranties often provide lifetime coverage for the original homeowner

Exterior warranties range from 2 years to 15 years for both residential and commercial applications.

3M™ window films are designed for durability, optical clarity, and resistance to fading, bubbling, or discoloration ensuring your investment continues to protect and perform for years to come.

It’s very uncommon, but in certain conditions window film can contribute to thermal stress that leads to glass breakage. Window film increases solar absorption, which can raise the temperature of the glass when exposed to direct sunlight. If that added stress exceeds what the specific piece of glass can handle, a crack may occur.

Whether thermal breakage occurs depends on several variables, including:

Glass type and edge quality

Existing chips, scratches, or defects

Exterior or interior shading (awnings, blinds, drapes)

Film type and solar absorption

Pane size, shape, and orientation

Indoor vs. outdoor temperature differences

These conditions vary from window to window — which is why professional evaluation is essential.

Starmor performs a detailed inspection of your glazing and uses industry-standard film-to-glass compatibility charts to select a film that is safe for your window type. Our installers also look for edge damage, manufacturing flaws, or environmental factors that could increase risk.

With decades of field experience across residential and commercial properties, Starmor makes informed film recommendations that significantly reduce the chance of thermal stress breakage.

Every film we install includes a minimum five-year glass breakage warranty against thermal shock fracture. If a covered window breaks within five years, the manufacturer will replace the glass (up to $500 per window), and Starmor will reinstall the film.

No — professionally selected and properly installed window films do not cause seal failure on dual-pane (insulated) glass units. When the correct film is applied to the interior pane, it can increase the glass temperature slightly, but the resulting change in airspace pressure is minimal and well within the limits that quality windows are designed to withstand.

Even a temperature increase of 20°F inside the sealed unit — which is higher than typical for most films — produces less than a 3% air pressure change. Insulated glass units are built and tested to tolerate over 20% pressure changes, far exceeding anything window film can generate.

Seal failure is almost always related to the quality and construction of the window itself, not the window film. All insulated glass units eventually fail over time, but:

High-quality windows last longer

Poorly constructed or inexpensive units fail sooner

Environmental exposure, manufacturing defects, and age are primary causes

Starmor evaluates your glass and selects film based on proven film-to-glass compatibility standards to ensure safe application. When the right film is chosen, the risk of window film contributing to seal failure is extremely low.

For customers concerned about longevity, the best protection is investing in well-made insulated windows from reputable manufacturers — paired with correctly specified window film.

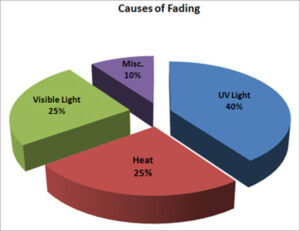

No window film can completely stop fading — but high-quality window films can significantly slow it down and help protect your furnishings, flooring, artwork, and fabrics from sun damage. Window film targets the three primary contributors to fading: ultraviolet light, visible light, and solar heat.

As a general rule:

UV radiation accounts for ~40% of fading

Visible light contributes ~25%

Solar heat contributes ~25%

Other factors (~10%) include humidity, interior lighting, pollutants, and material quality

Professional-grade films, such as 3M™ Sun Control Window Films, block up to 99% of UV rays and reduce both heat and visible light transmission. By addressing the major sources of fading, window film helps extend the life, appearance, and value of your interior furnishings.

We’re here to help! Please reach out with any questions or concerns, and we’ll get back to you as soon as possible. We look forward to hearing from you

We’re here to help! Please reach out with any questions or concerns, and we’ll get back to you as soon as possible. We look forward to hearing from you

Don’t wait another second — contact the Starmor team today to start planning your project!

Fill out the form below, and we will be in touch shortly.